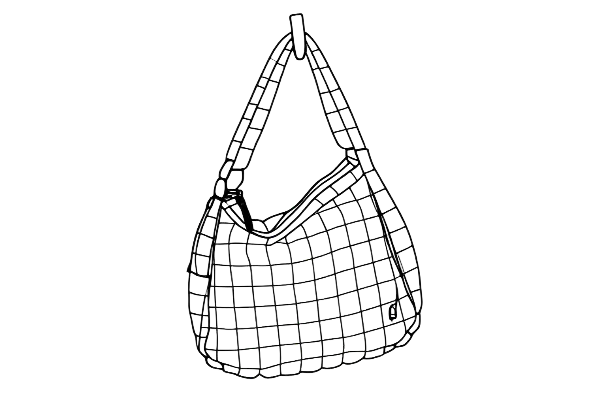

Customization Quilted Tote Bag Highlights

What You Can Choose

Premium Quilted Material – Soft-touch, lightweight, and durable

Multiple Styles Available – From minimalist to luxurious padded designs

Wide Color & Fabric Options – Nylon, polyester, cotton,

or vegan leather

Custom Branding Options – Logo embroidery, lining print,

zipper pull tags

What We Offer

OEM/ODM Manufacturing Services

MOQ starting from 100 pcs/style

Sample lead time: 7–10 days

Bulk lead time: 30–45 days

Custom quilting patterns & stitch density

Private label, packaging & logistics support

What We Offer

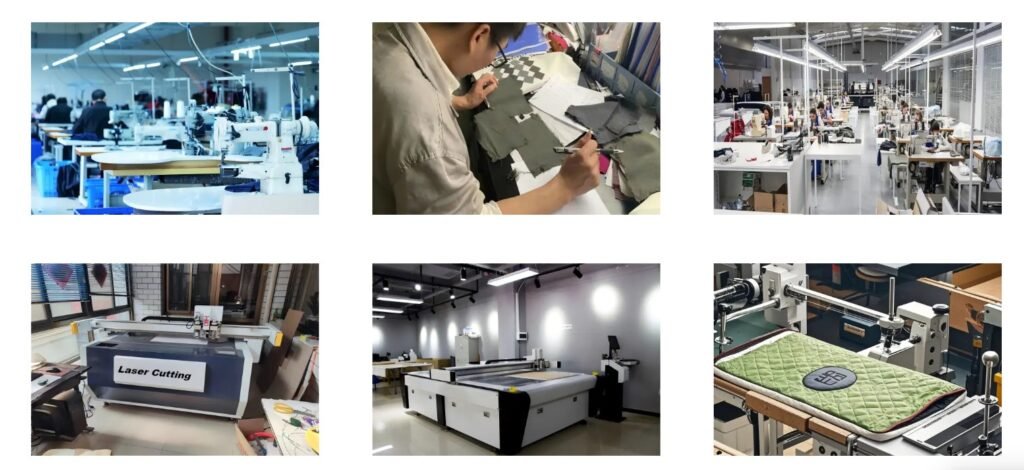

Where Quality Begins – Our Quilted Tote Bag Manufacturing Capabilities

Factory Overview

Over 600 skilled workers across 3 facilities

Monthly capacity: 100,000 quilted tote bags

In-house Sampling & QC Team

30+ pattern makers and technicians

Advanced Machinery

Computerized quilting machines & heavy-duty sewing lines

Durability Tested

Handles stress-tested for 10,000+ lifts

Why choose our tote bag

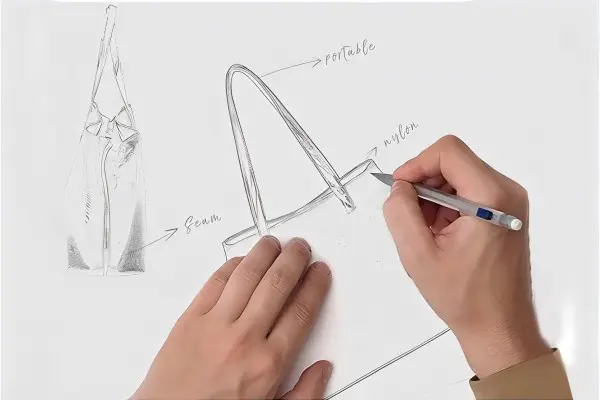

How We Customize Your Quilted Tote Bags Step by Step

step 1. Share Your Design or Idea

To ensure precise development of your custom quilted tote bag, please provide technical sketches, reference images, or structural specifications—such as required compartments, preferred quilting patterns, and any customized stitching details.

step 2. Select Outer Fabric, Padding & Lining

Outer Layer (nylon, satin, cotton-like fabrics, etc.)

Middle Padding (wadding, foam, or recycled filling materials)

Lining (cotton fabric, polyester, etc.)

Please also confirm the fabric texture, GSM (weight), waterproof properties, and any eco-certifications if required.

step 3. Custom Quilting Pattern Sampling

Key Steps Before Sampling:

Provide the quilting pattern (e.g., diamond, wave, or custom brand design)

The factory will test stitch spacing, quilting lines, and padding thickness to ensure suitability

Some brands may also require custom pressing/stitching molds for precision detailing

step 4. Sample Creation & Structure Testing

Full Sample Review Includes:

Checking if the quilting is smooth and evenly stitched

Ensuring the bag maintains its intended structure and shape (no sagging)

Verifying that internal pockets and hardware match the design specifications

Confirming the placement and execution of the logo embroidery or metal logo plate

step 5. Approval & Mass Production

Once the sample is approved, bulk production begins using industrial quilting machines to ensure consistency and precision.

step 6. Final Quality Check & Packaging

Key Quality Checkpoints:

Ensure stitching is neat with no breaks or skipped threads

Check for any misalignment in quilting patterns

Verify that padding is evenly distributed with no clumping

Confirm the bag holds its intended shape and structure

step 7. Shipment & Delivery

We support standard export packaging, custom packaging based on client requirements, or retail-ready packaging for direct sale.

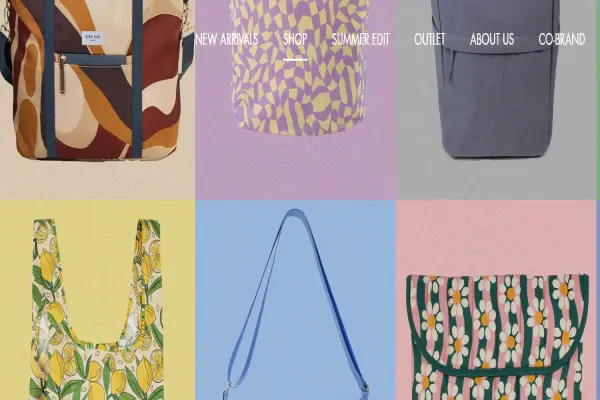

Supplying Quilted Tote Bags to Fashion, Wellness, and Gifting Brands

As a professional quilted tote bag supplier, we understand that functionality and brand alignment are critical across different industries. Whether you’re a fashion label seeking tactile, soft-touch designs, a retailer looking for high-durability commuter bags, or a DTC brand focused on high-volume weekend totes—quilted tote bags offer the flexibility, aesthetic appeal, and technical performance needed for modern consumers. With custom internal layouts, double-sided color options, and scalable production, our solutions are tailored to meet the diverse demands of B2B clients across fashion, lifestyle, and travel categories.

Fashion brands seeking soft-touch quilted totes

Based on market research feedback, the bag has reasonable partitions and multiple pockets, which improves user access efficiency by 30%. It is suitable for notes, snacks and a variety of personal items, meeting the needs of multiple scenarios.

Retailers launching padded commuter bags

The double-sided patterns and colors comply with Pantone® color standards. The reversible tote bag has passed a 5,000-cycle flip durability test, ensuring vibrant colors and structural stability remain intact after prolonged use without damage.

DTC brands creating quilted weekenders

The production lines are ISO 9001:2015 certified and use a ±1.0 ΔE color tolerance standard to ensure precise and consistent color matching for each batch of custom reversible tote bags. With a daily capacity of 5,000 units, we guarantee stable supply to meet large-scale order demands.

Case study:How Brand Y launched a best-seller quilted tote in 60 days

Brand Story

Brand Y is an emerging lifestyle brand based in Northern Europe, focusing on sustainable fashion products. Its target customers are commuting women and urban travelers aged 25-40. They hope to launch a quilted tote bag that is both lightweight and stylish to meet the multi-scenario needs of customers for daily commuting and weekend travel.

The Challenge

Brand Y is an emerging lifestyle brand based in Northern Europe, focusing on sustainable fashion products. Its target customers are commuting women and urban travelers aged 25-40. They hope to launch a quilted tote bag that is both lightweight and stylish to meet the multi-scenario needs of customers for daily commuting and weekend travel.

The Challenge

Brand Y is an emerging lifestyle brand based in Northern Europe, focusing on sustainable fashion products. Its target customers are commuting women and urban travelers aged 25-40. They hope to launch a quilted tote bag that is both lightweight and stylish to meet the multi-scenario needs of customers for daily commuting and weekend travel.

The First Step

We held a remote kick-off meeting with Brand Y’s design team to confirm their style direction, budget goals, and key functional requirements such as internal capacity, waterproofing needs, and shoulder strap width. Based on this, we recommended three quilting fabric options and color combinations.

The Second Step

Our sampling department completed the prototype within 7 days using recycled nylon material, accurately replicating the brand’s quilt pattern and inner layout. After brand testing and minor adjustments, we simultaneously initiated bulk material preparation.

The Last Step

Before mass production, we collaborated with the brand to finalize packaging and logistics plans, including brand labels, hang tags, and plastic-free packaging design. The bulk production took only 22 days, and the entire process from design to shipment was completed within 60 days.

The Outcome

Within the first month of launch, over 2,800 units were sold, making it the brand’s best-selling item. The quilted tote received overwhelmingly positive feedback on social media, with customers describing it as “light but structured.” Encouraged by the success, Brand Y expanded its quilted product line, resulting in a 37% increase in repeat purchases. The strong partnership led to a renewed collaboration to develop additional items, including quilted pouches and backpacks.

Final Review

“Working with your team has been a game-changer. You turned our idea into reality faster than we imagined — and the results speak for themselves. From fabric suggestions to final packaging, every step felt seamless and professional.”